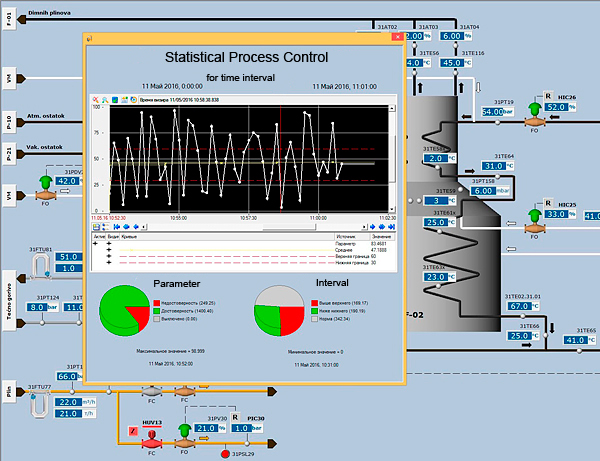

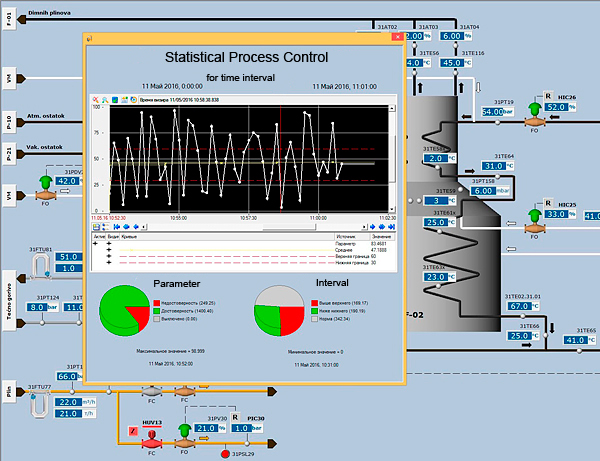

TRACE MODE SCADA/HMI supports statistical process control technologies - SPC which ensure the quality of process control, and therefore the output, predicting deviations from the norms and dealing with violations in the early stages.

Example. A control system keeps the technological process within the established limits and does not report any problems. However, the TRACE MODE SPC functions fix a steady drift in the mean value of an important parameter (for example, pressure), which is an early sign that the available controls do not cope with the process (for example, a slight depressurization occurred or the pressure relief valve is clogged). Having such information, the operator can prevent an accident at an early stage of its occurence, i.e. implement statistical process control.

Similarly, important information is carried by such parameters as the change in time of the standard deviation, dispersion, the number of the parameter's out-of-bounds per unit time, the extremal values, etc. All these parameters can be controlled by the TRACE MODE SCADA/HMI SPC module.

TRACE MODE SPC technologies provide the user with more options than traditional statistical process control systems (based on Shewhart control charts), because provide the calculation of statistical parameters of the process in real time, ensuring the possibility of early decision making - not only correct the problem, but also prevent it, achieving the best result.

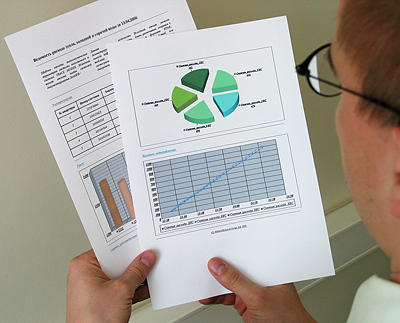

TRACE MODE SPC “on the fly” calculate the statistical parameters of the process deviations and acknoweledge the operator and keep records with the powerful TRACE MODE alarm management system. Information about the statistical values of the process can be written in reports that are automatically generated by the TRACE MODE Documentation Server. Based on these reports, you can create Schuhart control cards, or use a more modern method of real-time quality management, including advanced technologies for automatic and adaptive control.

TRACE MODE graphic tools ensure display of both quantitative SPC information and qualitative information in the form of pie or bar charts. Both quantitative and qualitative SPC information is available to the operator both in real time and in the form of HTML and XML reports that can be published to the WWW or viewed using MS Office programs, browsers and other means including via the Internet.

In real time, the TRACE MODE SIAD/SQL 6 archive can request the value of any parameter at a specified time (in the past) or a slice of values for a specified time interval, which allows the user to program the processing of historical data using standard TRACE programming languages. And in order to display on the SCADA / HMI screen a two-hour summary table on the main technological parameters, no programming is required, only the configuration of the corresponding attributes of the statistics collection channels.

SPC technologies are available in any TRACE MODE RTM by default - no additional SPC fee is required. |