AdAstrA Support team announce a new SCADA TRACE MODE 6.07 release. TRACE MODE 6.07 features new development tools for electricity metering systems and building automation. AdAstrA Support team announce a new SCADA TRACE MODE 6.07 release. TRACE MODE 6.07 features new development tools for electricity metering systems and building automation.

In recent years, TRACE MODE 6 SCADA/HMI has been increasingly adopted in energy accounting systems based on electric meters and other metering equipment from a variety of manufacturers. The standard method for data acquisition from meters was rather uncomfortable, because too many channels were required, and often users had to program even standard electricity metering functions manually.

The exciting new 6.07 release offers a new, unified way to process electricity metering data, which brings together features such as collecting data from meters made by different manufacturers, calculating standard characteristics, feeding data to upstream control rooms, visualising process, documenting process using standard forms, and submitting documents to electric companies.

Universal Electric Meter Driver

Starting with 6.07 release, SCADA TRACE MODE features an all-in-one driver that supports a variety of protocols used by different electricity meter manufacturers. The driver type can be configured in COM port settings (“Destinations”) of a node. While configuring a main system component, a developer can select the meter type from list and then view the meter specifications to choose any parameters to be controlled.

The driver currently supports the following models of electric meters and analysers:

- Iskra MIS (Slovenia): Iskra_MI, Iskra_MT, Iskra_MC, Iskra_WS

- Circutor (Spain): CVM_NGR, CVM_BD, CVM_K2

- Algodue Elettronica (Italy): UPM 303, UPM 304, UPM 305

- Incotex: Mercury 230, Mercury 233, Mercury 203.2Т;

- СЭТ-4ТМ2, СЭТ-4ТМ1, ПСЧ и СЭБ;

- Energomera: CE 102, CE 201, CE 303, CE 304, CE 315, ЦЭ6850;

We will continue improving the driver by adding support of other meters, based on TRACE MODE 6 users' requests.

The driver is supported both by RTM and Micro TRACE MODE for Windows CE, making it possible to use any controller running Micro TRACE MODE in an electricity metering system. The driver can communicate with meters using RS 232/485, modem, or GSM. The different types of meters can connect to a single bus. Whenever meters have specific rules regulating how a connection is established and disconnected, the driver can automatically enforce such rules, in accordance with each meter protocol. For better performance, we recommend configuring meter in a mode that does not require switching serial interface speeds.

Connecting a meter to a TRACE MODE project node is very easy:

- Create a “Sources/Receivers” layer component in your project and configure basic connection settings within it (meter type, COM port number, device number, ID, password, etc.).

- Next, link this component to the CALL channel of the ChGroupReq call type (“DEVICE”), which will execute all communication functions, as well as receive and archive data.

- Finally, link this channel arguments to the functional CALL_ ChGroupReq and use the latter to configure functions to be executed and respective meter parameters.

You can also configure similar functions with different runtime modes or change types and/or parameters of active functions in real time.

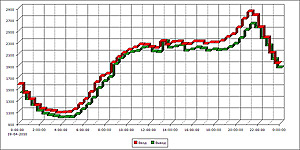

For each meter, individual logs are created automatically, containing averaged data such as power, energy statistics, and event list.

Archive volumes comply with the regulations applicable to electricity metering data archiving. Meter archive data are automatically collected from devices and saved to files. Plausible information from meter archives is fully synchronised. You can also pull archives and logs from any meter in a forced manner. All archive data can be processed using internal TRACE MODE tools to display trends or generate documents. Archive files are subject to sampling, with sampling results used for mathematical processing and further delivery to node channels, as necessary. Separate log files are used to register sessions and quality of TRACE MODE connection with meters.

If a selected meter cannot provide averaged data archives, the DEVICE can create such archives based on real time data from this meter. Whenever archive data stored in a meter are not read in a timely fashion or appear erroneous, you can add or adjust archive data manually or using a programme.

Current data collected from meters can be processed and archived to SIAD in a standard fashion. You can also average data directly in RTM archive instead of pulling averaged data archives from your device. Additionally, for all functional components of this method, internal DUMP function saves and restores data during reboots.

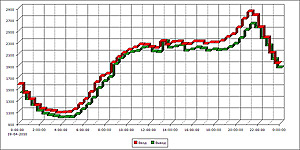

Imbalance Calculation Technology

Imbalance calculation is one of the most frequent challenges in electricity metering applications. TRACE MODE 6.07 features a mechanism designed to automatically calculate imbalances for each feeder as an absolute or relative value. To tackle this challenge, TRACE MODE 6.07 provides a special virtual component, SUMMATOR. While its basic configuration is similar to a DEVICE component of any meter, this component also includes a “virtuality” attribute: meters of cells related to a single feeder or meters related to different feeders within a feeding subassembly. Imbalance calculation is one of the most frequent challenges in electricity metering applications. TRACE MODE 6.07 features a mechanism designed to automatically calculate imbalances for each feeder as an absolute or relative value. To tackle this challenge, TRACE MODE 6.07 provides a special virtual component, SUMMATOR. While its basic configuration is similar to a DEVICE component of any meter, this component also includes a “virtuality” attribute: meters of cells related to a single feeder or meters related to different feeders within a feeding subassembly.

The SUMMATOR arguments are linked to the ChGroupReq_result channels, which are configured to execute calculation functions such as addition, absolute imbalance, or relative imbalance. When a required summary result is calculated, a Summator channel of respective group is activated to receive the requested time range. Archive sampling for meters of cells belonging to a group, and a meter of a respective feeder during the same time period is completed automatically, with processing results returned as the ChGroupReq_result channel arguments.

TRACE MODE now also includes a METER EMULATOR component designed to simulate electric meter operation, without providing a physical connection capability.

Electric Meter Licensing Policy in TRACE MODE 6.07

Any Professional line TRACE MODE development system supports an unlimited number of electric meters. Meters are polled using an all-in-one driver for electric meters (in runtime software, the number of supported meters depends on the number of available channels). You can, however, use meters for development and debugging purpose only (virtual meters). Any periodic meter polling will result in incorrect data in profiler.

The basic line development system and runtimes do not support the all-in-one driver for electric meters. You can use TRACE MODE 6 base version development system for evaluation purposes though, by using METER EMULATOR to receive data generated by TRACE MODE.

Both editions of the new release will continue to support the old mechanism of polling electric meters through channels or drivers.

The number of electric meters polled by the universal communication mechanism, with full data processing by SCADA TRACE MODE servers, depends on the number of channels licensed , as follows:

- 15 to 127 channels – 2 electric meters;

- 255 channels – 16 electric meters;

- 511 channels – 22 electric meters;

- 1,023 channels – 32 electric meters;

- 2,047 channels – 45 electric meters;

- 4,095 channels – 64 electric meters;

- 8,191 channels – 90 electric meters;

- 32,000 to 64,000 channels – unlimited number of electric meters.

Any TRACE MODE server can communicate with an unlimited number of electric meters polled by the all-in-one driver, if used exclusively for the purpose of feeding data to another TRACE MODE RTM. Any TRACE MODE server can communicate with an unlimited number of electric meters polled by the all-in-one driver, if used exclusively for the purpose of feeding data to another TRACE MODE RTM.

Similarly to RTM, some models of Micro TRACE MODE 6 for Windows CE can poll electric meters using two methods: a standard method based on channels or drivers and the new method introduced in 6.07 release, based on the all-in-one driver. The new method enables automatic data processing and standard power supply parameter calculation in the format widely used by power industry. The data are uploaded from meters to operator workstations based on TRACE MODE RTM.

The number of electric meters polled by the all-in-one driver depends on Micro TRACE MODE type and on the number of licensed channels. You can find this number in the price list. However, any Micro TRACE MODE 6 that supports electric meters can communicate with an unlimited number of electric meters polled by the universal communication mechanism, if used exclusively for the purpose of feeding data to TRACE MODE RTM.

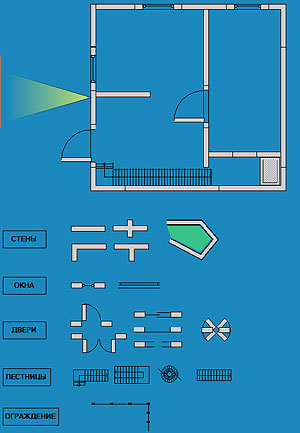

New Graphic Features in 6.07 Release

The 6.07 release includes a variety of new graphical items, including:

- “Control menu”: It provides control over control function execution. 2 arguments are used for this purpose. The first one receives a numeric command. Command execution is controlled by checking whether the other argument value matches the value configured in the settings.

- “Channel”: It can simultaneously display linked channel value, its ENCODING, and measurement unit. A parameter is dynamically controlled for plausibility, status, or any values outside of normal operating range, with all results displayed on the screen. By using this GI, an operator can directly acknowledge the last AR message from this channel and configure its control range limits in real time.

- “Database”: An on-screen table is linked using a screen argument to an SQL request that implements a request of several strings. Sampling result is saved to GI memory and displayed in the table. The operator can manage the request and sample the desired string from the table interactively.

- “Flat pump”: Colour dynamisation has been added to internal space and housing outline, and for rotor – to outline and filling.

- “Flat valve 2”: Unlike the existing GI “Flat valve 1”, the new GI features an independent component, “Drive”, which offers dynamisation of both outline colour and filling colour. The valve drive graphic form, selectable from 10 options, matches common actuator designs.

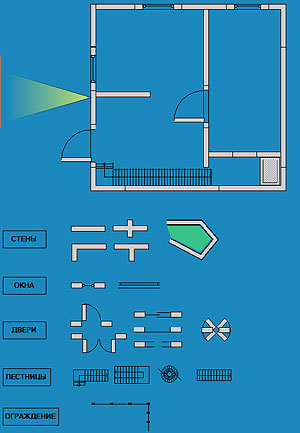

New graphical groups, “Areas”, “Building Elements”, and “Electrical Building Elements”, have been added, significantly extending the range of available GUI tools for building automation.

New Dynamisation Features:

TRACE MODE 6.07 includes the following new features:

- Independent visibility dynamisation for each graphical item;

- “Proportional switch” method available for switching to another screen;

- Dynamic transformation for graphical objects has been added. Transformation of any object and its graphical item can now be superposed;

- Control functions now allow programming “Confirmation” header and text;

- “Display type” property settings have been enhanced for dynamic attributes. Arg conditions in an interval and Set {Arg & Const1 = Const2} have been added;

- A command to link the range limits in indicators has been added;

- The “Display type” specification with “Blinking” property has been enhanced;

- Specification has been enhanced for those 3D graphical items that allow selecting material simulation;

- All painted graphical items with filling and other objects now have a transparency property. Several types of transparency gradients are available.

New Graphical Editor Features

HMI Editor now includes additional features, making it easier and faster to develop your graphic library:

- Graphical objects can now be used as screen headers;

- The graphical item properties window now has its own clipboard, making it possible to copy existing properties settings between graphical items;

- The graphical item properties now allow to directly select the placement layer and bind “Dynamic transformation” argument using D&D method;

- Tools for Z-positioning the screen layers have been enhanced;

- When a large screen is loaded in HMI Editor, an hour glass appears;

- A hotkey for showing/hiding a screen grid is now available (CTRL+G).

Enhanced Features of Individual Graphical Items

Some graphical items have been modified, including:

- “Node alarm report” – font selection is now possible;

- “Trend” now includes an access code to restrict access to curve properties configuration;

- You can now choose to move cursor “To time stamp”, whenever “Trend” is selected;

- Configuring “Hide at start” property is now possible for each trend curve;

- “Text from file” now displays HTML code generated in the memory;

- Digital information can now display in a binary format;

- “Picture-button” now supports text overlay, with the ability to dynamise both content and colour;

- The “Button group” now includes orientation (horizontal/vertical), linked argument value display, and watermark colour with transparency;

Improved RTM Dynamic Performance

We have added a host of features designed to dramatically reduce PC load, including:

- Economy mode of screen loading is now available;

- The process of exporting projects with graphical objects and loading projects into RTM has been optimised;

- Programmable control of pop-up screen display in real time is now possible. You can dynamically limit the number of concurrently open pop-up screens, including blocking pop-ups for individual static screens;

- Programmable re-binding of screen arguments in real time has been enhanced, making it possible to avoid loading same graphical templates in certain situations.

New Features

Serial communication redundancy is now available for communication with input/output modules.

New Protocol Support

The 6.07 release includes drivers for a number of widely-used controllers and protocols:

- IEC 60870-5-101 telemechanics protocol;

- IEC 60870-5-104 telemechanics protocol (master and slave)

New Software Products

The 6.07 release includes the following new software products:

Adaptive Micro TRACE MODE 6 OEM WinPAC-8000 for Windows CE: Designed to run logical programmes, manage and adjust processes, and display information in HMI embedded in WinPAC-8000 and ViewPAC controllers (also includes programmes for WinCON-8000). Provides adaptive PID and PDD loop self-adjustment. Adaptive Micro TRACE MODE 6 OEM WinPAC-8000 for Windows CE: Designed to run logical programmes, manage and adjust processes, and display information in HMI embedded in WinPAC-8000 and ViewPAC controllers (also includes programmes for WinCON-8000). Provides adaptive PID and PDD loop self-adjustment.

- Micro TRACE MODE 6 GSM/GPRS+ for WinPAC-8000 with open protocols (IEC 60870-5-104, IEC 60870-5-101, Modbus TCP slave) for Windows CE. Designed to collect data, run logical programmes, and display information in HMI embedded in WinPAC-8000 and ViewPAC controllers (also includes programmes for WinCON-8000). Supports I/O devices. Includes drivers for connecting electric meters, with fully automatic data processing (63 to 127 channels – one meter, over 127 channels – 2 meters). Supports an unlimited number of electric meters polled for

the purpose of feeding data to RTM (functioning as a data collection and transfer device only). Polls meters and remote I/O devices via modems and GSM modems, including using IEC-60870-5-101 or IEC-60870-5-104 master. Connects to PC using RS, network, or GPRS, including using Modbus TCP, IEC-60870-5-101, or IEC-60870-5-104 slave. the purpose of feeding data to RTM (functioning as a data collection and transfer device only). Polls meters and remote I/O devices via modems and GSM modems, including using IEC-60870-5-101 or IEC-60870-5-104 master. Connects to PC using RS, network, or GPRS, including using Modbus TCP, IEC-60870-5-101, or IEC-60870-5-104 slave.

- Micro TRACE MODE 6 GSM/GPRS + for Windows CE for metering systems: Functions as a data hub and controller in electricity metering systems based on different controllers running Windows CE (x86 and ARM) – Tion, WinPAC, ViewPAC, etc. Includes integrated drivers for electric meters polled by the universal communication mechanism, with automatic processing. Supports an unlimited number of electric meters polled for the purpose of feeding data to RTM (functioning as a data collection and transfer device only).

The new release is available for download for all registered users at the SUPPORT section at www.adastra.ru.

CAUTION! Because this release includes many new graphical features, compatibility problems are possible with previous releases. Please make sure you back up any work created using previous releases, before you upgrade to the 6.07 release.

If you have questions, please visit http://forum.adastra.ru/.

|

AdAstrA Support team announce a new SCADA TRACE MODE 6.07 release. TRACE MODE 6.07 features new development tools for electricity metering systems and building automation.

AdAstrA Support team announce a new SCADA TRACE MODE 6.07 release. TRACE MODE 6.07 features new development tools for electricity metering systems and building automation.

Imbalance calculation is one of the most frequent challenges in electricity metering applications. TRACE MODE 6.07 features a mechanism designed to automatically calculate imbalances for each feeder as an absolute or relative value. To tackle this challenge, TRACE MODE 6.07 provides a special virtual component, SUMMATOR. While its basic configuration is similar to a DEVICE component of any meter, this component also includes a “virtuality” attribute: meters of cells related to a single feeder or meters related to different feeders within a feeding subassembly.

Imbalance calculation is one of the most frequent challenges in electricity metering applications. TRACE MODE 6.07 features a mechanism designed to automatically calculate imbalances for each feeder as an absolute or relative value. To tackle this challenge, TRACE MODE 6.07 provides a special virtual component, SUMMATOR. While its basic configuration is similar to a DEVICE component of any meter, this component also includes a “virtuality” attribute: meters of cells related to a single feeder or meters related to different feeders within a feeding subassembly.  Any TRACE MODE server can communicate with an unlimited number of electric meters polled by the all-in-one driver, if used exclusively for the purpose of feeding data to another TRACE MODE RTM.

Any TRACE MODE server can communicate with an unlimited number of electric meters polled by the all-in-one driver, if used exclusively for the purpose of feeding data to another TRACE MODE RTM.

Adaptive Micro TRACE MODE 6 OEM WinPAC-8000 for Windows CE: Designed to run logical programmes, manage and adjust processes, and display information in HMI embedded in WinPAC-8000 and ViewPAC controllers (also includes programmes for WinCON-8000). Provides adaptive PID and PDD loop self-adjustment.

Adaptive Micro TRACE MODE 6 OEM WinPAC-8000 for Windows CE: Designed to run logical programmes, manage and adjust processes, and display information in HMI embedded in WinPAC-8000 and ViewPAC controllers (also includes programmes for WinCON-8000). Provides adaptive PID and PDD loop self-adjustment.

the purpose of feeding data to RTM (functioning as a data collection and transfer device only). Polls meters and remote I/O devices via modems and GSM modems, including using IEC-60870-5-101 or IEC-60870-5-104 master. Connects to PC using RS, network, or GPRS, including using Modbus TCP, IEC-60870-5-101, or IEC-60870-5-104 slave.

the purpose of feeding data to RTM (functioning as a data collection and transfer device only). Polls meters and remote I/O devices via modems and GSM modems, including using IEC-60870-5-101 or IEC-60870-5-104 master. Connects to PC using RS, network, or GPRS, including using Modbus TCP, IEC-60870-5-101, or IEC-60870-5-104 slave.

or compatibility with the Microsoft operating system Windows 8.1.

or compatibility with the Microsoft operating system Windows 8.1.

On January 30, 2007, a new release of the integrated SCADA-system TRACE MODE 6.05 has been made available, both in Professional and Standard editions.

On January 30, 2007, a new release of the integrated SCADA-system TRACE MODE 6.05 has been made available, both in Professional and Standard editions.  In the SCADA TRACE MODE 6.04 the support of Mitsubishi controllers using FX Computer Link and DeviceNet protocols was improved. The new driver is now integrated in the TRACE MODE 6.04 development system.

In the SCADA TRACE MODE 6.04 the support of Mitsubishi controllers using FX Computer Link and DeviceNet protocols was improved. The new driver is now integrated in the TRACE MODE 6.04 development system.

The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin

The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin  TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust.

TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust. A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia).

A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia). Learn how to connect a Mitsubishi Melsec FX3U PLC to TRACE MODE SCADA/HMI through built-in driver with our new free online video training.

Learn how to connect a Mitsubishi Melsec FX3U PLC to TRACE MODE SCADA/HMI through built-in driver with our new free online video training.

A Belgorod based AIT company (South of Russia) has successfully used TRACE MODE SCADA/HMI software to develop and to implement a batch control system for manufacturing of fodder additives. The control system has been installed in facility of TeknoFeed (Tshebekino, Belgorod area, Russia).

A Belgorod based AIT company (South of Russia) has successfully used TRACE MODE SCADA/HMI software to develop and to implement a batch control system for manufacturing of fodder additives. The control system has been installed in facility of TeknoFeed (Tshebekino, Belgorod area, Russia).

AdAstra Company (Russia) announced the release of real-time monitor (LinRTM) for the operating system Linux.

AdAstra Company (Russia) announced the release of real-time monitor (LinRTM) for the operating system Linux.  In Bosnia, the Bosanski Brod refinery launched a second production line, which was repaired by the Russian company Zarubezhneft. Now the plant is able to produce the gasoline conforming to the Euro 5 standard.

In Bosnia, the Bosanski Brod refinery launched a second production line, which was repaired by the Russian company Zarubezhneft. Now the plant is able to produce the gasoline conforming to the Euro 5 standard.  AdAstra Research Group (Moscow, Russia) has released a new version of the free TRACE MODE SCADA/HMI driver for the OMRON programmable logical controller. The new driver is built in the TRACE MODE SCADA/HMI 6.09 release and above.

AdAstra Research Group (Moscow, Russia) has released a new version of the free TRACE MODE SCADA/HMI driver for the OMRON programmable logical controller. The new driver is built in the TRACE MODE SCADA/HMI 6.09 release and above.

The Iron–Technik company (Ust -Kamenogorsk, Kazakhstan), an AdAstra authorized system integrator, has launched into commercial operation an automation system for municipal public utility named "Oskemen" (Ust -Kamenogorsk, Kazakhstan ).

The Iron–Technik company (Ust -Kamenogorsk, Kazakhstan), an AdAstra authorized system integrator, has launched into commercial operation an automation system for municipal public utility named "Oskemen" (Ust -Kamenogorsk, Kazakhstan ).