Baoshan Iron & Steel Plant is the biggest metal plant in China. In January 2004, a SCADA/HMI and softlogic process control system for air and oil supply to the rolling mill was successfully launched in the steel-rolling shop of Plant No. 3. The system has been developed by engineers of Silian Corporation, the biggest state instrument-making Chinese corporation. Baoshan Iron & Steel Plant is the biggest metal plant in China. In January 2004, a SCADA/HMI and softlogic process control system for air and oil supply to the rolling mill was successfully launched in the steel-rolling shop of Plant No. 3. The system has been developed by engineers of Silian Corporation, the biggest state instrument-making Chinese corporation.

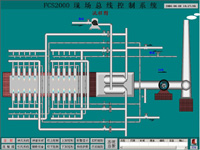

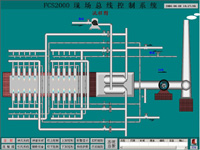

The process control system has been made in the SoftDCS architecture. It is based on FCS-2000 redundant PC-based controllers under control of Micro TRACE MODE softlogic software, remote I/O cards and TRACE MODE SCADA/HMI. According to an OEM-agreement signed with AdAstra, Silian completes the FCS-2000 controller with TRACE MODE SCADA/HMI and softlogic software. The connection between Micro TRACE MODE and input/output modules is carried out through the Modbus RTU protocol built into TRACE MODE.

Operator workstations are based on Double Force RTM (SCADA/HMI) with hot redundancy system. Additional client HMI have been developed with the use of Internet technologies based on TRACE MODE Web-Activator (10 thin client web HMI).

In a process control system, ТRACE MODE SCADA performs the following functions:

- data acquisition;

- data logging;

- remote equipment control;

- alarming;

- information displaying on trends;

- report generation.

"A successful launch of the process control system of air and oil supply to a rolling mill at the Shanghai Metal Plant is very important", says Mr. Chen Ksue Zhun, Deputy Director, Technical Centre, Silian Corporation, - "The experience of implementation of this project strengthens the position of our FCS-2000 system on the market. TRACE MODE is a reliable system. We are sure that TRACE MODE SCADA/HMI and softlogic software will be used in China at many enterprises".

Before the beginning of works, Chinese specialists have passed training in the TRACE MODE Authorised Centre in Moscow. |

Baoshan Iron & Steel Plant is the biggest metal plant in China. In January 2004, a SCADA/HMI and softlogic process control system for air and oil supply to the rolling mill was successfully launched in the steel-rolling shop of Plant No. 3. The system has been developed by engineers of

Baoshan Iron & Steel Plant is the biggest metal plant in China. In January 2004, a SCADA/HMI and softlogic process control system for air and oil supply to the rolling mill was successfully launched in the steel-rolling shop of Plant No. 3. The system has been developed by engineers of

The Silian corporation, one of the main AdAstrA's OEM-partners in China, has completed the development of DCS-system at the Yong Xin Sugar factory in the Guang Xi province (China).

The Silian corporation, one of the main AdAstrA's OEM-partners in China, has completed the development of DCS-system at the Yong Xin Sugar factory in the Guang Xi province (China). The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin

The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin  TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust.

TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust. A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia).

A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia). On 24 April, 2006 AdAstrA Research Group has opened the Beijing Representative office. The office will focus on technical support for Chinese users of TRACE MODE SCADA software and will co-ordinate building of the Chinese national network of system integrators and dealers. Special attention will be given to the close OEM co-operation with Chinese instrumentation companies.

On 24 April, 2006 AdAstrA Research Group has opened the Beijing Representative office. The office will focus on technical support for Chinese users of TRACE MODE SCADA software and will co-ordinate building of the Chinese national network of system integrators and dealers. Special attention will be given to the close OEM co-operation with Chinese instrumentation companies.  ZAO PIK ZEBRA (Moscow, Russia) the AdAstrA's system partner has completed development and successfully implemented control system for the power unit 1 (800 MWt) at Talimardjan heat power plant (Uzbekistan). The control system is based on KRUIZ DCS and SOFTLOGIC and HMI software TRACE MODE.

ZAO PIK ZEBRA (Moscow, Russia) the AdAstrA's system partner has completed development and successfully implemented control system for the power unit 1 (800 MWt) at Talimardjan heat power plant (Uzbekistan). The control system is based on KRUIZ DCS and SOFTLOGIC and HMI software TRACE MODE.

Advantech Corporation (Taiwan) has presented the Advantech eBuilding Automation System, the control system for its own office building in Beijing based on the Russian

Advantech Corporation (Taiwan) has presented the Advantech eBuilding Automation System, the control system for its own office building in Beijing based on the Russian

The Complex Information Systems Co. (Kazakhstan) together with Namip Industrial Solutions Co.(Russia) have finished the first stage of manufacturing control system for one of the Kazakhstan's largest plant Atyrau Oil Refinery.

The Complex Information Systems Co. (Kazakhstan) together with Namip Industrial Solutions Co.(Russia) have finished the first stage of manufacturing control system for one of the Kazakhstan's largest plant Atyrau Oil Refinery.  AdAstra Research Group, Ltd signed a new partnership agreement for TRACE MODE SCADA/HMI distribution in Europe.

AdAstra Research Group, Ltd signed a new partnership agreement for TRACE MODE SCADA/HMI distribution in Europe.  Elna Company, the AdAstra's authorized system integrator, has developed a new serial project: the process control system for low-capacity gas-turbine power plants up to 12 MW.

Elna Company, the AdAstra's authorized system integrator, has developed a new serial project: the process control system for low-capacity gas-turbine power plants up to 12 MW.