Belelektromontazhnaladka company has successfully implemented a control system of the gas-engine heat and power plant in Anadyr city (Extreme Nord of Russia). The total power capacity of the gas-engine heat and power plant is 25 MW. Belelektromontazhnaladka company has successfully implemented a control system of the gas-engine heat and power plant in Anadyr city (Extreme Nord of Russia). The total power capacity of the gas-engine heat and power plant is 25 MW.

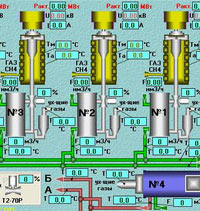

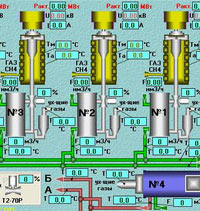

At the operator level of new control system, TRACE MODE SCADA/HMI software is used, while Mitsubishi Electric controllers are used at the hardware level. The system controls the gas-engine heat and power plant and 25 kW substations in Anadyr. The new control system of the gas-engine heat and power plant combines the heat and power processes to enable control over power supply, ventilation, heating, domestic and hot water supply, water conditioning, heat recovery, fire safety and the fuel and lubricant warehouse.

The TRACE MODE SCADA/HMI based control system for the gas-engine heat and power plant ensures complete hardware and software redundancy, therefore increasing the system reliability in the event of emergency. The data are communicated to the control system via the fiber-optic channels connecting controllers and data collection servers. This improves communication speed between devices, while making the system more robust.  For all controllers, the system provides a 20 ms acquisition cycle. Based on the calculation, a maximum acquisition cycle of 65 ms is expected. By connecting the controllers in a redundant ring, the system can easily maintain communication, even in the event of failure at one of the optical channel sites. For all controllers, the system provides a 20 ms acquisition cycle. Based on the calculation, a maximum acquisition cycle of 65 ms is expected. By connecting the controllers in a redundant ring, the system can easily maintain communication, even in the event of failure at one of the optical channel sites.

On the software level, the control system of the gas-engine heat and power plant is powered by SCADA TRACE MODE Double Force RTM+ redundant servers obtaining information from the controllers, classifying it within a database, and providing data storage and easy access capabilities. Using the OРС server, the SCADA TRACE MODE redundant servers collect data from both redundant controllers through the fiber-optic network and send them to the database.

In the control system of the gas-engine heat and power plant, the SCADA TRACE MODE  servers offer the capabilities below: servers offer the capabilities below:

- communication with the system controllers;

- collection and primary processing of the equipment status data;

- diagnostics of the controller network and network communication speed between the controllers and server;

- archiving information necessary to analyze activities of the operational staff and function of technology equipment for at least 7 days (archive can be extended up to 60 days);

- real-time technical and economic performance calculation;

- generating and printing emergency, start and daily logs;

- networking capability, including local workstation connection.

The data acquisition servers enable connection of the operators' workstations (AWS) powered by TRACE MODE RTM+ and TRACE MODE Netlink Light. The workstations can access the data archived at the servers. The software at the workstations provides access only to information requested by the given user.

The automated workstations running under SCADA TRACE MODE offer the features below:

- visualization and control of the processes by providing the process equipment maps, where the control points and measured parameter values are indicated;

- visualization of the process development and historical data trends;

- processing alerts and events;

- displaying warning/alarm/alert messages, and providing a path to eliminate emergency and unusual situations in the process.

The gas-engine heat and power plant was launched in 2006, and has generated 18,712 MW/h of electricity since then. Shortly, the new gas-engine heat and power plant will be able to deliver enough power to satisfy the needs of 15 thousand citizens of the local city. With migration to using natural gas as their main fuel, they will be able to also reduce environmental stress by eliminating harmful substances discharge into atmosphere due to coal use, decrease the cash cost of the electric and heat power, and improve power supply quality and reliability.

Currently, Belelektromontazhnaladka team is working to deploy a control system at Anadyrskiy power centre. This project aims to automate all substations within the town of Anadyr. |

Belelektromontazhnaladka company has successfully implemented a control system of the gas-engine heat and power plant in Anadyr city (Extreme Nord of Russia). The total power capacity of the gas-engine heat and power plant is 25 MW.

Belelektromontazhnaladka company has successfully implemented a control system of the gas-engine heat and power plant in Anadyr city (Extreme Nord of Russia). The total power capacity of the gas-engine heat and power plant is 25 MW. For all controllers, the system provides a 20 ms acquisition cycle. Based on the calculation, a maximum acquisition cycle of 65 ms is expected. By connecting the controllers in a redundant ring, the system can easily maintain communication, even in the event of failure at one of the optical channel sites.

For all controllers, the system provides a 20 ms acquisition cycle. Based on the calculation, a maximum acquisition cycle of 65 ms is expected. By connecting the controllers in a redundant ring, the system can easily maintain communication, even in the event of failure at one of the optical channel sites. servers offer the capabilities below:

servers offer the capabilities below:

In the SCADA TRACE MODE 6.04 the support of Mitsubishi controllers using FX Computer Link and DeviceNet protocols was improved. The new driver is now integrated in the TRACE MODE 6.04 development system.

In the SCADA TRACE MODE 6.04 the support of Mitsubishi controllers using FX Computer Link and DeviceNet protocols was improved. The new driver is now integrated in the TRACE MODE 6.04 development system. The China's largest piano manufacturer Beijing XINGHAI Musical Instruments has chosen SCADA TRACE MODE and PLC Mitsubishi for the process control of the gas purification system.

The China's largest piano manufacturer Beijing XINGHAI Musical Instruments has chosen SCADA TRACE MODE and PLC Mitsubishi for the process control of the gas purification system.

The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin

The Ho Chi Minh City based (Viet Nam) Duc Phong Technology and Automation Corporation (DPTA) has the status of AdAstrA Authorized Dealer. The corporatin  TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust.

TECHNOLOGY CORPORATION AND GERMAN STYLE AUTO was established in 2006, with a team of professionals, engineers, management staff are formally trained, motivated and experienced customers always trust. A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia).

A Riga city based Sia Rameda company (Riga , Latvia) has used russian made TRACE MODE SCADA/HMI software to develop a control system for ventilation, heating and cooling equipment in the RD Holding commercial and office center in Riga (street Maskavas 240, Riga , Latvia). Learn how to connect a Mitsubishi Melsec FX3U PLC to TRACE MODE SCADA/HMI through built-in driver with our new free online video training.

Learn how to connect a Mitsubishi Melsec FX3U PLC to TRACE MODE SCADA/HMI through built-in driver with our new free online video training.

A Belgorod based AIT company (South of Russia) has successfully used TRACE MODE SCADA/HMI software to develop and to implement a batch control system for manufacturing of fodder additives. The control system has been installed in facility of TeknoFeed (Tshebekino, Belgorod area, Russia).

A Belgorod based AIT company (South of Russia) has successfully used TRACE MODE SCADA/HMI software to develop and to implement a batch control system for manufacturing of fodder additives. The control system has been installed in facility of TeknoFeed (Tshebekino, Belgorod area, Russia).

AdAstra Company (Russia) announced the release of real-time monitor (LinRTM) for the operating system Linux.

AdAstra Company (Russia) announced the release of real-time monitor (LinRTM) for the operating system Linux.  In Bosnia, the Bosanski Brod refinery launched a second production line, which was repaired by the Russian company Zarubezhneft. Now the plant is able to produce the gasoline conforming to the Euro 5 standard.

In Bosnia, the Bosanski Brod refinery launched a second production line, which was repaired by the Russian company Zarubezhneft. Now the plant is able to produce the gasoline conforming to the Euro 5 standard.  AdAstra Research Group (Moscow, Russia) has released a new version of the free TRACE MODE SCADA/HMI driver for the OMRON programmable logical controller. The new driver is built in the TRACE MODE SCADA/HMI 6.09 release and above.

AdAstra Research Group (Moscow, Russia) has released a new version of the free TRACE MODE SCADA/HMI driver for the OMRON programmable logical controller. The new driver is built in the TRACE MODE SCADA/HMI 6.09 release and above.

The Iron–Technik company (Ust -Kamenogorsk, Kazakhstan), an AdAstra authorized system integrator, has launched into commercial operation an automation system for municipal public utility named "Oskemen" (Ust -Kamenogorsk, Kazakhstan ).

The Iron–Technik company (Ust -Kamenogorsk, Kazakhstan), an AdAstra authorized system integrator, has launched into commercial operation an automation system for municipal public utility named "Oskemen" (Ust -Kamenogorsk, Kazakhstan ).